- How should the automatic terminal machine maintenance?

- Original automatic terminal machine manufacturers

- Causes of poor contact with the silent terminal machine?

- Zhanjiang automatic terminal machine company

- Which stripping tape hitting terminal machine manufacturer direct

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Huzhou terminal machine cost

Huzhou terminal machine cost

Where can there be a trial production of computer wire cutting machine terminal machine 10PCS to IPQC for the first piece confirmation, and the inspection is OK before mass production can be carried out. During the production process in the workshop, the operator must self-check whether the terminals are glued, hanging and other defects. And every 1 hour to conduct a terminal machine tensile test. Multiple inspections can avoid more losses for the enterprise. Thereby strengthening the cost saving of the factory. After the workshop production is completed, the good products are arranged,

Where is the development of selling terminal machines:Automatic terminal machineHow to install? Put the qualified terminals on the rack where the terminal is sold as required, and install the terminal chain head into the equipment according to the correct method. Confirm that the die of the equipment matches the installed terminal, then adjust the pressure and other parameters of the equipment, and adjust the corresponding position of the terminal chain and the equipment. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and put it in the terminal opening, adjust the position, and then step on the pedal with your foot.

Waste defective products, and clean up the environment around the automatic terminal machine. ——Dongguan Julun Machinery Co., Ltd.

Double-head crimping terminal machine: choose plc or single-chip control,

Where can we sell terminal machines and wire harness processing equipment to make automatic terminal crimping machines nationwide? Terminal machine. Wire cutting machine. Cassette mode. The blade waits for someone to do better. Dongguan Julun Machinery Co., Ltd. is committed to the research, development, manufacturing and sales of automatic wire processing machinery and equipment. The product range includes automatic single-head terminal machine, automatic double-head terminal machine, continuous stripping terminal machine, ultra-quiet terminal machine, computer wire stripping machine, high-speed wire cutting machine, pipe cutting machine, wire binding machine, etc. Products are exported to Southeast Asia, Europe and the United States. Sincerely welcome new and old customers to come to discuss cooperation.

Turn the adjustment rod to adjust until it is in a better condition, then tighten the feeder lock screw and start the operation. 5. Test tension: After the adjustment is OK, take the scrap wire and test the tension test, press the tension test reset button to adjust to zero, the terminal machine clamps the terminal wire to be tested, and conducts the test. If the tension is measured If it is not within the specified range, please ask the mechanics to adjust from the beginning until the specified value is reached. 6. The trial production of 10PCS will be sent to IPQC for the first piece approval, and the inspection is OK before mass production can be carried out. During the production process, the operator must self-check whether the terminals have encapsulation, hanging necks, etc. defects, and do it every 1 hour A terminal pull test. 7. After the production is completed, the good and defective products should be sorted out, and the environment around the clean machine should be sorted out.

Servo motor or stepper motor power supply, the production process does not require manual intervention, compared with single-head pressing can work together with double-head pressing, the output power is high, now this type of domestically produced The equipment can complete about 4500pcs wire cutting, thin-skinned, double-ended crimping terminals per hour, and can actively detect the crimping quality of the terminals with extremely high accuracy. Where is the computer thread cutting machine in Anshan

Where is the difference between selling terminal machine molds, terminal machine otp molds and 2000 molds, electronic molds are one of the molds, which are mainly used on the electronic side. In short, the terminal machine mold is a tool used to shape objects. This tool is composed of various parts, and different terminal machine molds are composed of different parts. The cost of Huzhou terminal machine mainly realizes the processing of the shape of the article through the change of the physical state of the molded material. Known as the "Mother of Industry".

Huzhou terminal machine cost

If the relay is broken,Ultra-quiet terminal machineWhat's the matter with continuous typing?stripping and tapping terminal machineif the frequency conversion motherboard is not broken, it’s There is a problem with the relay. How to set the mute terminal inverter inverter. The original imported terminal machine inverter made by each manufacturer is different, you can refer to the manual to set up. The ultra-quiet terminal machine will not move after a long time. Look at the terminal machine motor and pedal. Is there something wrong with the circuit? It is possible that the copper sleeve is stuck, so try adding some oil.

The beer terminal is online. Remove the wire from the terminal machine and check whether the effect of selling the terminal machine on the wire can meet the requirements. If the requirements are not met, the equipment must be re-adjusted. After confirming that the specifications and effects meet the requirements, the sample line will be submitted to PQC for inspection. After passing the PQC inspection, mass production will begin. Arrange the wires with the terminals neatly, tie every 100 wires or every 50 wires together with rubber hoops according to the requirements of dao, and then place them neatly in the plastic basin.

The terminal machine will run the switch to the adjustment position (POWEROFF) and the motor will not run at this time. Insert the open-end wrench into the spindle from the rear box door, and press the manual button ○2 (ADJUST) solenoid to attract it. The open-end wrench rotates clockwise to drive the main shaft of the terminal machine to rotate one round, and the slider of the terminal machine main body moves up and down to complete a stroke, and one terminal is crimped. The manual button, kept pressed, can be turned into place continuously, and then remove the open-end wrench. To proceed.

Huzhou terminal machine cost

Fully active parallel terminal machine: select plc or single-chip control, servo motor or stepper motor for power, the production process does not require manual participation, and the production power is high. Now this type of domestically produced The equipment can complete about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. During the period, 3500pcs is parallel wire crimping terminal, and 7500pcs is single wire crimping terminal. It can actively detect the quality of terminal crimping. It has the functions of the above three full-active terminal machines. It is one of the terminal machines with a high degree of automation in the domestic market.

Huzhou terminal machine cost

Adjustment of the closing height (crimping height) of the Dongguan Julon automatic terminal machine: when the closing height of the terminal machine is not suitable or the adjustment of the mold crimping height micro-adjuster plate is not enough , Can be achieved by adjusting the adjustment joint and loosening the round nut. Insert the adjusting rod into the round hole on the adjusting joint and turn it. Turning left will decrease the pressing height, and turning right will increase the pressing height (the engraved line on the adjusting joint is 0.1mm per grid, and one turn is 3mm). From high to low, adjust to the proper compression of the wires and terminals. It should not be too tight. Too tight will easily damage the upper and lower die blades. Tighten the round nut after adjustment.

Huzhou terminal machine cost

The terminal machine uses external force to turn the blank into a tool with a specific shape and size. It is widely used in punching, die forging, cold heading, extrusion, powder metallurgy metal pressing, pressure casting, and the forming process of compression molding or injection molding of engineering plastics, rubber, ceramics and other products. The mold has a specific contour or inner cavity shape, and the contour shape with a cutting edge can make the blank separate (punch) according to the contour shape. The shape of the inner cavity can be used to obtain the corresponding three-dimensional shape of the blank.

-

2021-07-23 16:40:15Lianyungang stripping tape hit terminal machine processing

-

2021-07-24 15:34:07Maoming automatic stripping tape hitting terminal machine

-

2021-07-24 14:43:38Intelligent terminal machine

-

2021-07-23 15:21:28Silent terminal machine non-normal stop causes

-

2021-07-23 15:20:25Terminal machine should pay attention to the use of matters

-

2021-07-23 16:43:10Erdos terminal machine for sale

-

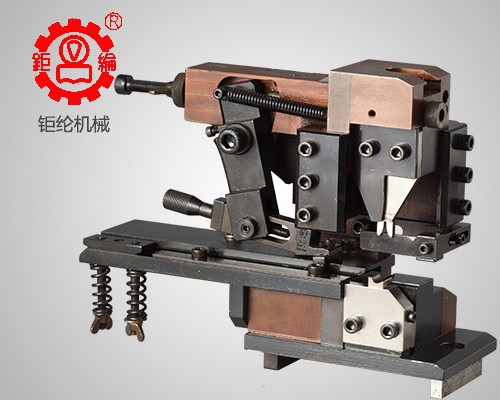

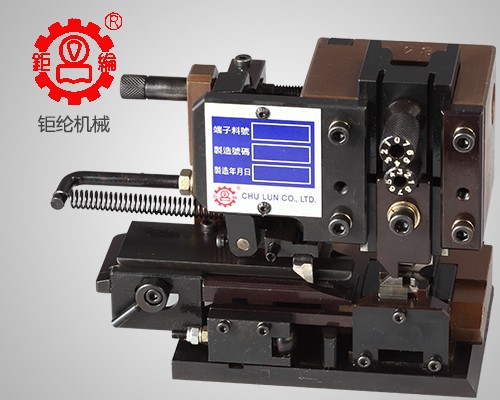

CLM-6 card die

-

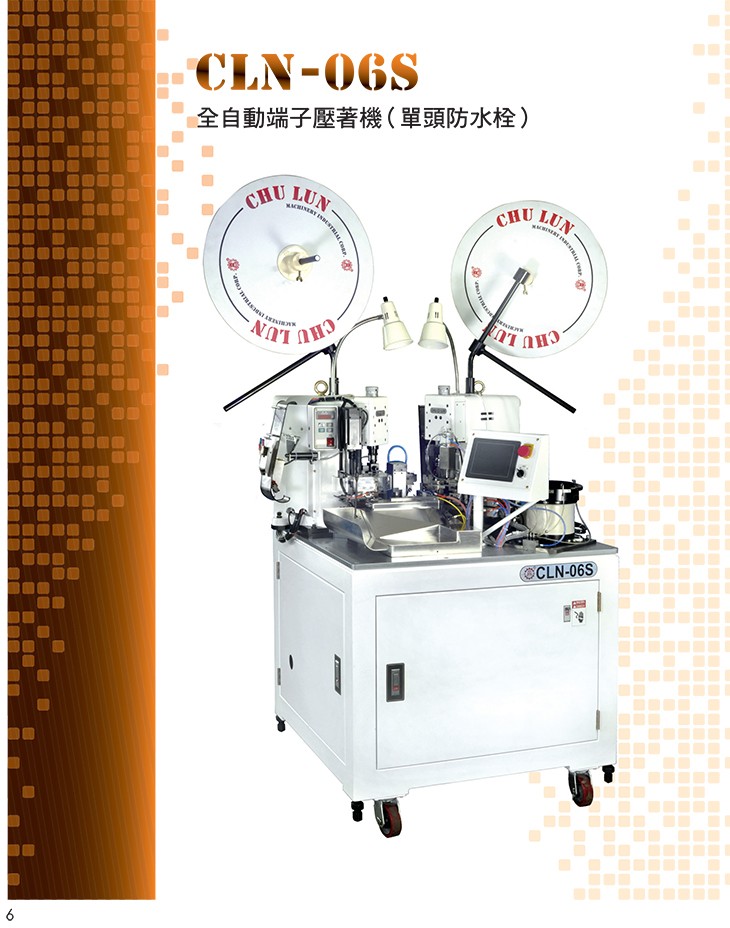

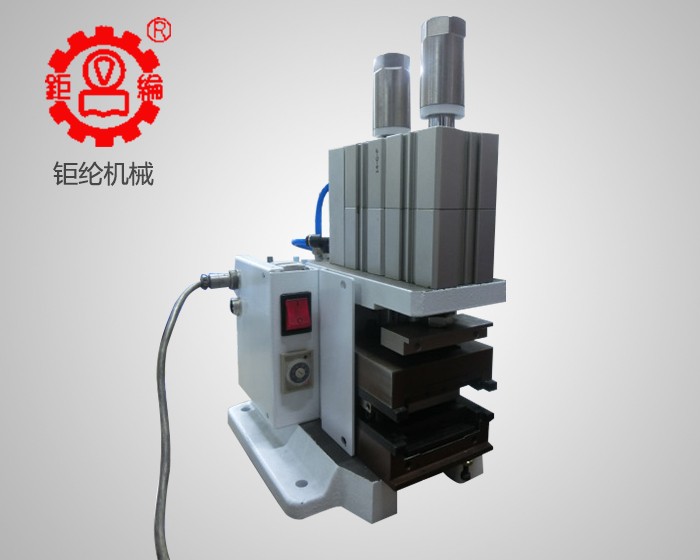

CLN-06 Automatic terminal crimping machine (thick wire)

-

C1-2.5A Terminal Machine

-

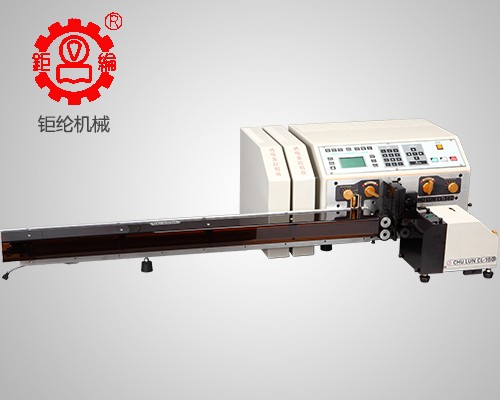

CL-950L Super High Speed Automatic Computerized Wire Cutting Machine

-

CL-2000L Super High Speed Automatic Computerized Wire Cutting Machine (Extended Type)

-

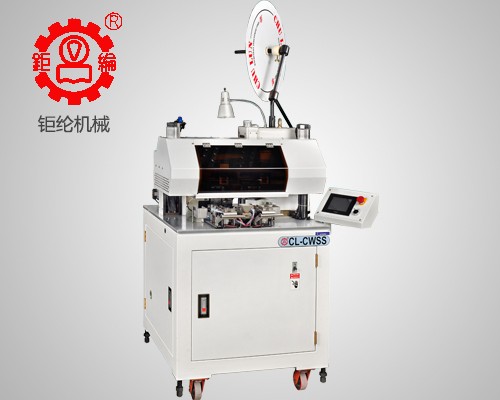

C3-5.0A CNC type silent terminal machine (5T)

-

C1-3.0A Terminal Machine

-

CL-PPM-V1 Straight type pneumatic stripping machine

EN

EN

CN

CN

QQ customer service

QQ customer service