- Erdos terminal machine for sale

- Maoming automatic stripping tape hitting terminal machine

- Huzhou automatic terminal machine processing factory

- Mute terminal machine non-normal stop causes

- Automatic terminal machine history and future?

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Erdos terminal machine for sale

Ordos terminal machine for sale

Where is there a computerized wire cutting machine terminal machine for trial production? 10PCS will be sent to IPQC for first piece confirmation, and the inspection is OK before mass production can be carried out. In the workshop production process, the operator must self-check Check whether there are defects such as rubber encapsulation, hanging neck, etc. on the terminals, and conduct a terminal machine tensile test every 1 hour. Multiple inspections can avoid more losses for the enterprise. Thereby strengthening the cost saving of the factory. After finishing the production in the workshop, arrange the good products,

Where is the development of terminal machines:Automatic terminal machineHow to install? Place the qualified terminals on the terminal rack wherever required, and install the terminal chain head into the equipment according to the correct method. Confirm that the die of the equipment matches the installed terminal, then adjust the pressure and other parameters of the equipment, and adjust the corresponding position of the terminal chain and the equipment. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and put it in the terminal opening, adjust the position, and then step on the pedal with your foot.

Waste defective products, and clean up the environment around the automatic terminal machine. ——Dongguan Julun Machinery Co., Ltd.

Double-head crimping terminal machine: choose plc or single-chip control,

Excessive pressure on the stripping terminal machine or other problems, check and debug to OK. Before operation, check each locking screw and confirm that there is no looseness inside. When the blade of the automatic terminal machine has undergone 200,000 times of stamping, there will be a certain degree of wear. At this time, the riveted terminal may have defective products. The cutting blade of the equipment has experienced 1 million or even 2 million times. After the cutting and stripping, there will be certain hidden dangers. Therefore, in the use process of high-demand customers, it is necessary to strictly control the service life of the wearing parts, and the correct operation of the equipment can also reduce the loss.

Where is the classification of terminal machines: How many square wires should be used for how many tonnage terminal machines, terminal machines can be classified into automatic terminal machines, stripping and tapping machines, ultra-quiet Terminal machine, pneumatic terminal machine, terminal machine, computer wire automatic stripping and terminal machine, pin terminal machine, gold wire terminal machine, etc. 1. Fully automatic terminal machine can be divided into: 1. Fully automatic single-head crimping terminal machine (using PLC or single-chip control, this type of domestic equipment can realize about 5000pcs wire cutting, peeling, and single-end crimping terminal per hour. It can automatically detect the crimping quality of the terminal, which is more popular in the domestic market)

Servo motor or stepper motor power supply, the production process does not require manual intervention, compared with single-head pressing can work together with double-head pressing, the output power is high, now this type of domestically produced The equipment can complete about 4500pcs wire cutting, thin-skinned, double-ended crimping terminals per hour, and can actively detect the crimping quality of the terminals with extremely high accuracy. Where is the computer thread cutting machine in Anshan

Stripping and terminal-stripping machineThe mold generally includes two parts: a movable mold and a fixed mold (or a punch and a female mold) , The two can be separated or combined. The parts are taken out when they are separated, and the blanks are injected into the mold cavity to form when they are closed. The mold is a precision tool with a complex shape and can withstand the expansion force of the blank. It has high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy. The development level of mold production is an important symbol of the level of mechanical manufacturing. one. Where are the problems encountered with terminal machine molds

Ordos terminal machine for sale

If the relay is broken, the ultra-quiet terminal machine always keeps hitting it, and if the frequency conversion motherboard of the stripping terminal machine is not broken, it means that there is a problem with the relay. How to set the mute terminal inverter inverter. The original imported terminal machine inverter made by each manufacturer is different, you can refer to the manual to set up. The ultra-quiet terminal machine will not move after a long time. Look at the terminal machine motor and pedal. Is there something wrong with the circuit? It is possible that the copper sleeve is stuck, so try adding some oil.

Failure of the stripping and crimping machine: the crimping terminal is bad. The crimping terminal may be completely crimped, or the crimping position is not reached, which causes the copper wire to be exposed. At this time, the stripping terminal machine needs to check whether the gun-type swing arm conduit is installed on the wire. Whether the terminal blade of the swing arm catheter is relatively straight; whether the auxiliary press block of the terminal is loose; check whether the interval between the terminal and the automatic machine has been changed. Check again after making changes. Only after there is no problem can the terminal machine continue to work.

Poor peeling of the stripper and terminal machine: the peeling time varies. There are many reasons for different stripping lengths. The common stripping length is too tight or too loose. At this time, it is only necessary to properly adjust the open space between the two wheels until the wire cannot be pulled by hand. On the other hand, this may be a problem with the blade. The blade is cut too deep or too shallow, and even the blade is installed at an angle, which may also cause this result. At this time, it is necessary to adjust the position of the blades as needed. If it is caused by damage to the blade, it is recommended to replace the blade immediately. Inconsistent cutting lengths Inconsistent cutting lengths may be due to blade or blade wear; to encounter such a problem, simply replace the cutter with a new one.

Ordos terminal machine for sale

Fully active parallel terminal machine: select plc or single-chip control, servo motor or stepper motor for power, the production process does not require manual participation, and the production power is high. Now this type of domestically produced The equipment can complete about 7000pcs of wire cutting per hour and 11000pcs of terminal crimping. During the period, 3500pcs is parallel wire crimping terminal, and 7500pcs is single wire crimping terminal. It can actively detect the quality of terminal crimping. It has the functions of the above three full-active terminal machines. It is one of the terminal machines with a high degree of automation in the domestic market.

Ordos terminal machine for sale

Where is the market demand for terminal machines: the difference between semi-automatic terminal machines and automatic terminal machines? Which is better? 1. The automatic terminal machine is a terminal machine that integrates a server (silent type). Its operating principle is not the same as that of a general terminal machine. It only needs to send a message to the server, and this information is then transmitted to the motor. A movement can be made by attacking the automatic terminal machine. 2. Semi-automatic terminal machine, we generally call it terminal machine, which is the kind of vertical desktop terminal machine that we often see in the general market now.

Ordos terminal machine for sale

Where is the working principle of the terminal machine Brief introduction: The terminal machine refers to the machine used for wire processing, which can press the hardware head to the end of the wire. Then do conduction. The terminal produced by the terminal machine is usually for more convenient connection, and the two wires can be connected together stably without welding. And only need to unplug the power plug when disassembling. Where is the working principle of the terminal machine? 1. (Stepping principle) The motor keeps rotating. There is a circuit breaker in the clutch, and each action is a standard "O", which is very common. 2. In the past five years, there was a (silent) terminal with a server. Its working principle is different from the above. It just sends a message to the server and then transmits it to the motor to perform the operation.

-

2021-07-24 14:09:20Zhanjiang automatic terminal machine company

-

2021-07-24 14:43:38Intelligent terminal machine

-

2021-07-24 15:50:44Xi'an special price super quiet terminal machine

-

2021-07-23 15:23:54Automatic terminal machine production precautions

-

2021-07-23 17:01:46Huzhou automatic terminal machine processing factory

-

CL-TST-150 Automatic Push-Pull Test Machine

-

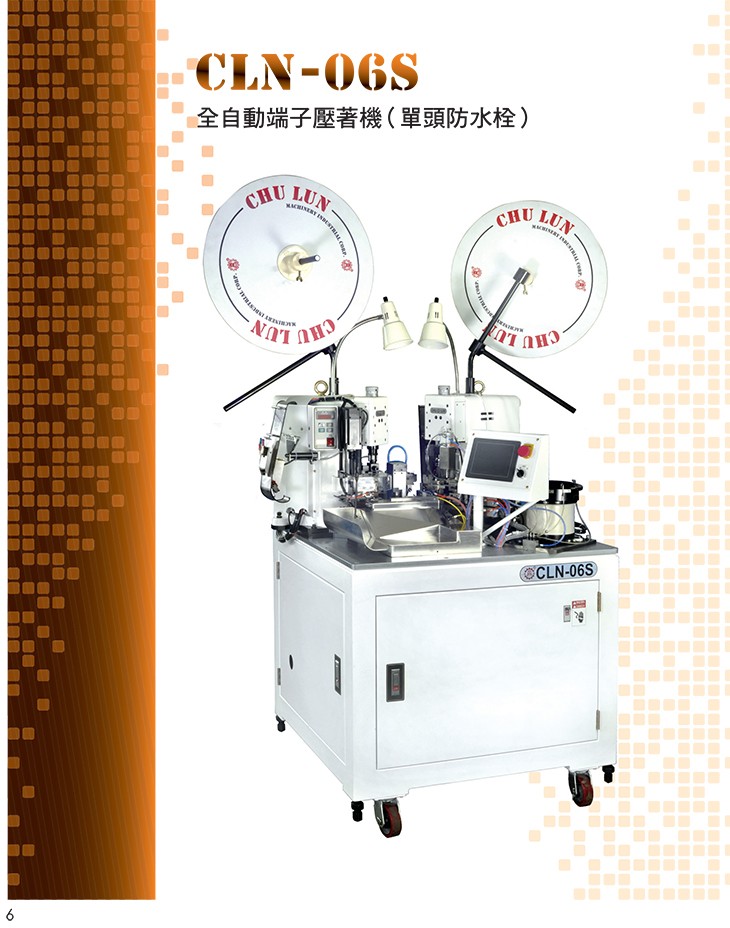

CLN-06 Automatic terminal crimping machine (thick wire)

-

CLT-C2S with stripping and beating terminal machine

-

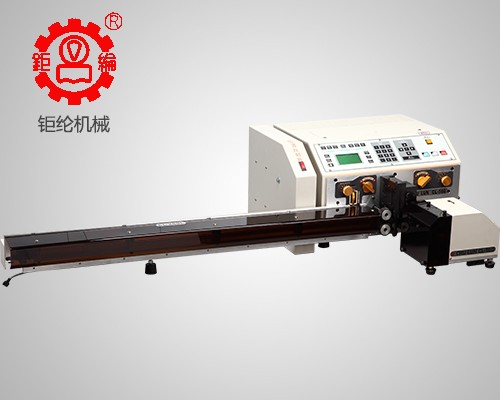

CL-560+160+260L Automatic Computerized Wire Cutting Machine

-

CL-CWSS Single Head Short Wire Solder Dip Machine

-

WRS-04 Shaft Loading Type Unwinder

-

CLN-05CHS Automatic Double Head Solder Dip Machine

-

CL-950N Super Speed Automatic Computerized Wire Cutting Machine

EN

EN

CN

CN

QQ customer service

QQ customer service