- Original automatic terminal machine manufacturers

- Qingdao terminal machine production

- How should the automatic terminal machine maintenance?

- Automatic terminal machine production precautions

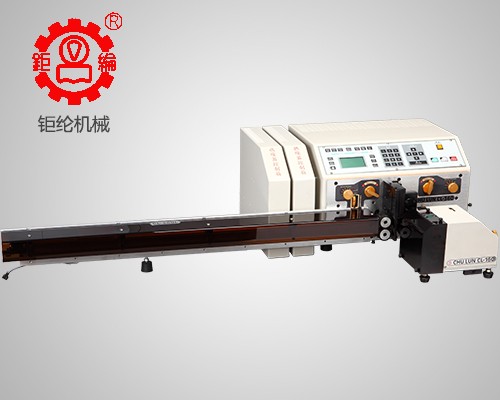

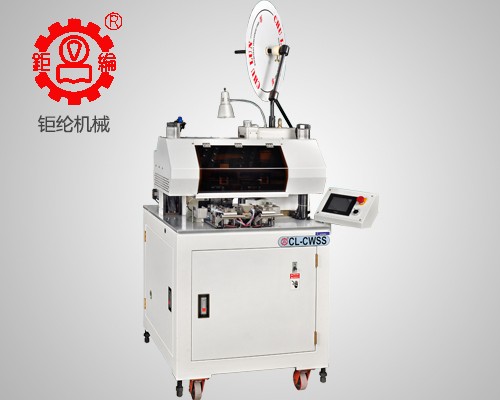

- Computerized Wire Cutting Machine

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Lianyungang stripping tape hit terminal machine processing

Fully automatic terminal machine is a more convenient machine, we should also know this, fully automatic mechanical equipment Those with greater help can save a lot of labor and increase the output of the factory. It can also help the factory to temporarily relieve the problem of not being able to find workers. However, we are also using the fully automatic terminal machine when we use it. There will be a problem. Some time-division automatic terminal machines will have relatively loud noises after being used for a period of time. We should all be aware of this!

Lianyungang stripping and tapping machine processing

Dongguan Julun Machinery Co., Ltd. adheres to the quality policy of "quality first, pursuit of customer satisfaction, continuous innovation, and endless improvement" to serve customers. It insists on purchasing reliable raw materials, advanced equipment and 1653 technology; it implements strict scientific management and fast on-time delivery, strict quality control, and production updates. Better computer wire stripping machines, terminals and other products can meet the needs of domestic and foreign markets. At the same time, the details of the production process are strictly controlled internally. In order to achieve higher quality assurance.

The length of the wire cut is inconsistent. A: The wire feed wheel is pressed too tightly or too loosely. Countermeasure: Adjust the straightening machine so that it can be straightened and sent out smoothly. There are two differences between professional production of terminal machines and automatic terminal machines. The first is the characteristics of the automatic terminal machine: the automatic terminal machine is an automatic machine that integrates wire feeding, wire cutting, stripping, terminal punching and other chemical machinery. The automatic terminal machine was developed and manufactured in Japan as early as, the operator only needs to touch the screen button to send information to the server, and then to the motor. The fully automatic terminal machine can complete all actions such as wire feeding, wire cutting, stripping, and terminal tapping within one second. Strip terminal machineThe processing of the same kind of line, after the equipment runs continuously for 1 hour, To re-check to confirm the length of the wire opening and stripping and whether the wire opening effect is qualified. After confirming the qualification, you can continue to produce the terminal machine operation method of Dongguan Julun Machinery. You can try the five installation steps of the automatic terminal machine. 1. Preparations before the operation of Dongguan Julun's automatic terminal machine: (1) Check whether the crimping machine and die are installed firmly, and whether the foot switch and the power socket are firmly inserted.

What is the working principle of the new terminal machine? 1. (Principle) The motor keeps rotating. There is a breaker inside with a clutch, and every time it is moved, an "O" marked with preparation comes out, which is very common. 2. In the past five years, there has been a (silent) terminal machine with a server. Its operating principle is different from the above. It only sends a message to the server, which is then transmitted to the motor to complete an action. Fully automatic terminal machine: As long as the wire is put on, the terminal mold is set up, and the parameters are set in the screen, it can be produced.

As a humanized and intelligent high-end technology product, the automatic terminal machine is suitable for large, medium and small enterprises that need to use wire harnesses. It can save a lot of labor and is efficient Several times the semi-automatic terminal machine.

Check whether the power supply voltage of the stripper terminal machine is consistent with the specified voltage (220V). Fix the terminal roll and guide the terminal into the die through the guide plate. Adjust the crimping height and manually operate the pressure test terminal. After turning the spindle into place with an open-end wrench, remove the open-end wrench. 2. Manual operation of Dongguan Julun automatic terminal machine: Turn the operation switch to the adjustment position (POWEROFF) and the motor will not run at this time. Insert the open-end wrench into the spindle from the rear box door, and press the manual button (ADJUST) solenoid to attract it. The open-end wrench rotates clockwise to drive the main shaft to rotate one round, the main machine slide block moves up and down to complete a stroke, and a terminal is crimped. Keep pressing the manual button (ADJUST) to turn it in place continuously, and then remove the open-end wrench.

Lianyungang stripping and tapping machine processing

Generally, it is normal to have fine noise. If it is a loud one, then there are these two problems, a. There is abrasion between certain parts and components of the terminal machine, which leads to increased conflicts; b. The screw of the terminal machine is loose during work, causing the parts to vibrate and become rugged.

The market demand for the new terminal machine: What is the difference between a semi-automatic terminal machine and a fully automatic terminal machine? Which is better? 1. The automatic terminal machine is a terminal machine that integrates a server (silent type). Its operating principle is not the same as that of a general terminal machine. It only needs to send a message to the server, and this information is then transmitted to the motor. A movement can be made by attacking the automatic terminal machine. 2. Semi-automatic terminal machine, we generally call it terminal machine, which is the kind of vertical desktop terminal machine that we often see in the general market now.

Lianyungang stripping and tapping machine processing

The working principle of the semi-automatic terminal machine, the diagram is to put the qualified terminals on the terminal frame according to the requirements, and install the terminal chain head into the equipment according to the correct method. Recognize the equipment knife mold Match with the installed terminal, then adjust the pressure and other parameters of the pressure monitoring, and adjust the corresponding position of the terminal chain and the device. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and the terminal opening, adjust the position, and then step on the foot pedal with your foot to put the terminal on the wire.

The safety of the new terminal machine: talk about the functional advantages of the new automatic terminal machine. The advantages of the new automatic terminal machine are introduced as follows: the new automatic terminal machine refers to the processing requirements of the wire The machine used, also known as the fully automatic stripping and pressing end machine, is a new type of equipment that has just been released in recent years. It is a multifunctional machine integrating feeding, cutting, stripping and pressing. It is humane and intelligent. The high-end technology products are suitable for large, medium and small enterprises, saving labor. Increase work efficiency.

Lianyungang stripping and tapping machine processing

Fully automatic terminal machine: As long as the wire is threaded, the terminal mold is set up, and the parameters are set in the screen, it can be produced. Terminal machines can be classified into pneumatic terminal machines, terminal machines, ultra-quiet terminal machines, automatic terminal machines, continuous terminal cutting PIN machines, continuous stripping terminal machines, semi-automatic ultra-quiet terminal machines, wire stripping terminal machines, and terminal blocks Machine, stripping machine, small diamond terminal machine, series motor stator terminal machine, computer wire automatic stripping machine, pin terminal machine, gold wire terminal machine, etc. The step angle of my stepping motor is 1.2 degrees, and the motor rotates a circle to drive the axis to move at a distance of 200mm. Now I am subdividing the drive to 1000 steps/revolution. Now the actual movement distance of the motor is 300mm. How many pulses do I need? Can it be moved to 300mm? Ask a master to help in the calculation, how to calculate it.

Lianyungang stripping and terminal processing machine

Dongguan Julun Machinery Co., Ltd. is engaged in the production and sales of new terminal machines, computer stripping machines, wire and cable processing equipment 2113. Wire harness connector processing equipment and various connectors. .Service as a professional enterprise. The company has a large number of professional and technical personnel, a strong after-sales service system and advanced precision processing equipment. Its electrical and mechanical accessories are imported from Taiwan 5261 and Japan, combined with advanced technical experience in Europe, America and Taiwan , Continue to develop, innovate, and provide customers with 4102 high-quality, high-efficiency products and services

-

2021-07-24 14:29:16Silent terminal machine inspection method

-

2021-07-23 16:56:22Which stripping tape hitting terminal machine manufacturer direct

-

2021-07-23 17:10:31Wuhu automatic terminal machine factory

-

2021-07-24 15:11:15Semi-automatic terminal machine

-

2021-07-24 14:29:50Shenzhen multiplayer exhibition fl

-

2021-07-23 16:43:10Erdos terminal machine for sale

-

C3-2.5S High-speed stripping and pressing machine

-

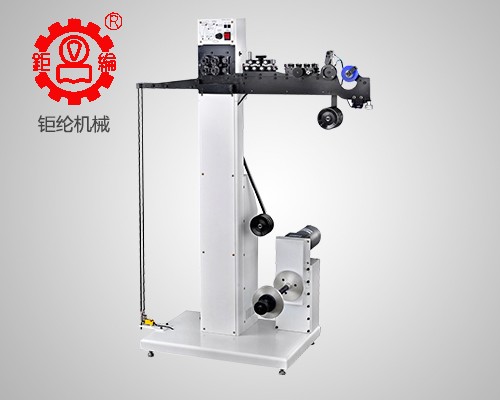

WRS-07 Multifunctional Wire Feeder

-

C1-2.5A Terminal Machine

-

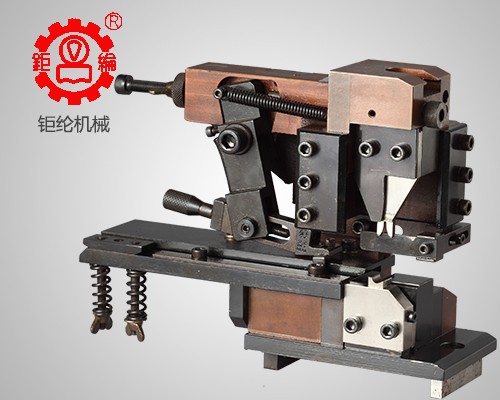

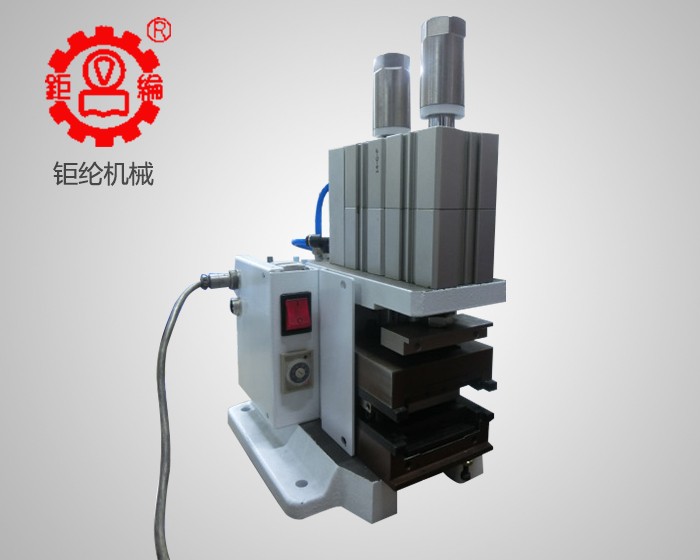

CLM-4E card die

-

CL-PPM-V1 Straight type pneumatic stripping machine

-

CLM-4S mode card die holder

-

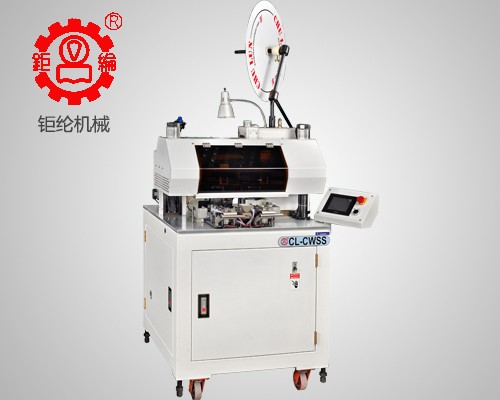

CL-CWSS Single Head Short Wire Solder Dip Machine

-

CL-CWSS Single-head pole short wire dip tin machine

EN

EN

CN

CN

QQ customer service

QQ customer service