- Zhuzhou sales intelligent terminal machine

- Which stripping tape hitting terminal machine manufacturer direct

- Terminal machine should pay attention to the use of matters

- Causes of poor contact with the silent terminal machine?

- Foshan automatic terminal machine wholesale price

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

How should the automatic terminal machine maintenance?

Automatic terminal machineIt is used in many factories, because it is a fully automatic product, so for us It has a very important role. This can avoid our manpower. One person can control several machines, which greatly saves labor and can bring us economic assistance. The manufacturers should all Knowing that workers on the assembly line are hard to find, so the fully automatic products have helped us very well, soAutomatic terminal machineHow should we maintain it? Tell us about the automatic terminal machine manufacturer.

Automatic terminal machine maintenance

The guide rail of the terminal punching machine must have a lubricating oil hole on the top of each terminal for 1 hour. 2-3 drops of air are suitable. The operator must clean the machine every day. Debris and remaining grease on the surface of the dust collector. The main high-speed bearing terminal must add butter every week, but remember not to add too much.

The specific operation method is as follows: open the back cover of the terminal machine, remove the clamp ring and remove the driven pulley, butter (evenly spread on the surface of the high-speed bearing), recovery (careful : In this process, when disassembling the pulley, pay attention to the loss of the bearing ball) After the two-stage repair is used for 3-6 months, the terminal machine needs to be checked whether all parts (lost) need to be replaced with belts and other accessories. The spring replacement is less elastic of. Whether the mechanical locking screw is loose, check whether the tension spring is deformed.

This isAutomatic terminal machine maintenance method , We can understand, this is also a great help for us, especially for manufacturers who use fully automatic terminal machines. After the maintenance is good, we will get better when the products are produced. The same can be Improve the power produced.

-

2021-07-23 15:23:06Automatic terminal machine history and future?

-

2021-07-23 16:40:15Lianyungang stripping tape hit terminal machine processing

-

2021-07-23 16:46:05Huzhou terminal machine cost

-

2021-07-24 14:29:50Shenzhen multiplayer exhibition fl

-

2021-07-24 15:58:23Xianyang small semi-automatic terminal machine

-

2021-07-24 15:11:15Semi-automatic terminal machine

-

C2-1.2 terminal machine

-

CLM-4E card die

-

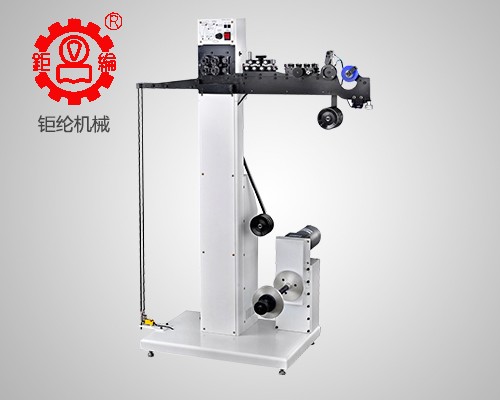

CL-RSS Automatic Terminal Crimping Machine (Single Head Thin Wire)

-

C1-3.0A Terminal Machine

-

C3-5.0A CNC type silent terminal machine (5T)

-

WRS-07 Multifunctional Wire Feeder

-

Fully Automatic Terminal Crimping Machine (Single Head Waterproof Bolt)

-

CL-RSB Automatic Terminal Crimping Machine (single head thick wire)

EN

EN

CN

CN

QQ customer service

QQ customer service