- Taiyuan automatic terminal machine manufacturing

- Automatic terminal machine production precautions

- Ningbo automatic terminal machine brand

- Maoming automatic stripping tape hitting terminal machine

- Why just purchased back the mute terminal machine will be fixed poorly?

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Zhuzhou sales intelligent terminal machine

Zhuzhou sells smart terminal machines

Fully automatic terminal machine is a more convenient machine, we should also know this, fully automatic mechanical equipment Those with greater help can save a lot of labor and increase the output of the factory. It can also help the factory to temporarily relieve the problem of not being able to find workers. However, we are also using the fully automatic terminal machine when we use it. There will be a problem. Some time-division automatic terminal machines will have relatively loud noises after being used for a period of time. We should all be aware of this! So what are the specific reasons for the formation?

Zhuzhou sales intelligent terminal machine automatic terminal machine safety inspection before operation: (1) Confirm that the wrench has been removed. (2) Tighten the round nut after adjustment. The automatic terminal machine operates normally: (1) Press the operating switch to the working position, and the pressure monitoring motor starts to operate. (2) Place the wire in the proper position of the terminal crimping position, and the crimped terminal must be in the middle of the upper and lower die cutters. (3) Step on the foot switch, and the main slider will push down to complete the crimping of the wire and the terminal, and send the next terminal to the crimping position. (4) Repeat the above steps to achieve continuous crimping between the wire and the terminal.

Generally, it is normal to have fine noise. If it is a loud one, then there are these two problems, a. There is abrasion between certain parts and components of the terminal machine, which leads to increased conflicts; b. The screw of the terminal machine is loose during work, causing the parts to vibrate and become rugged.

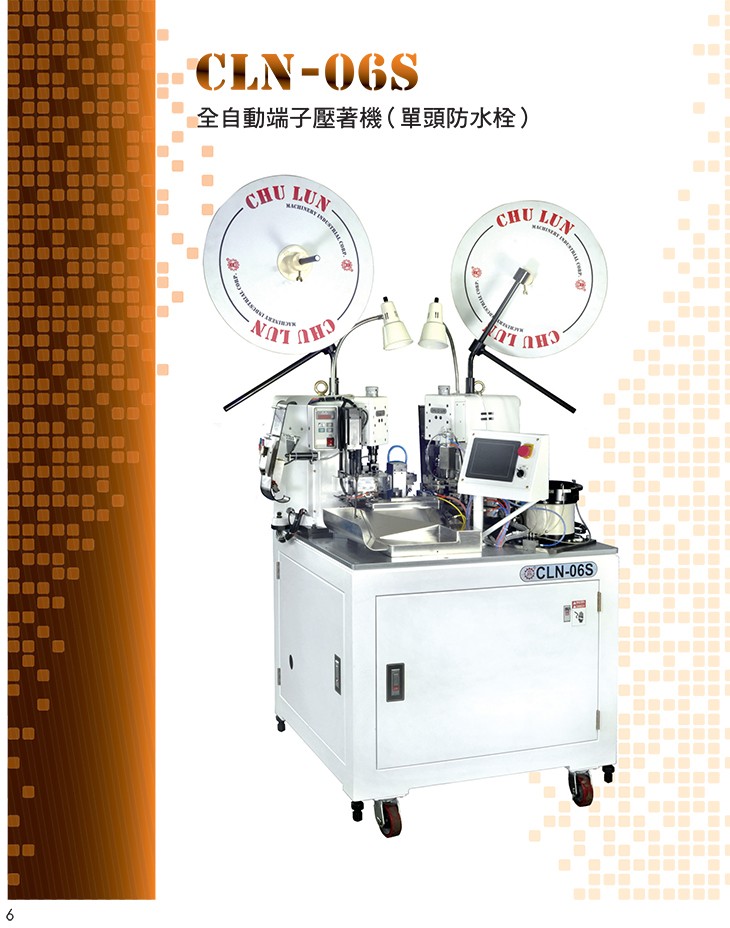

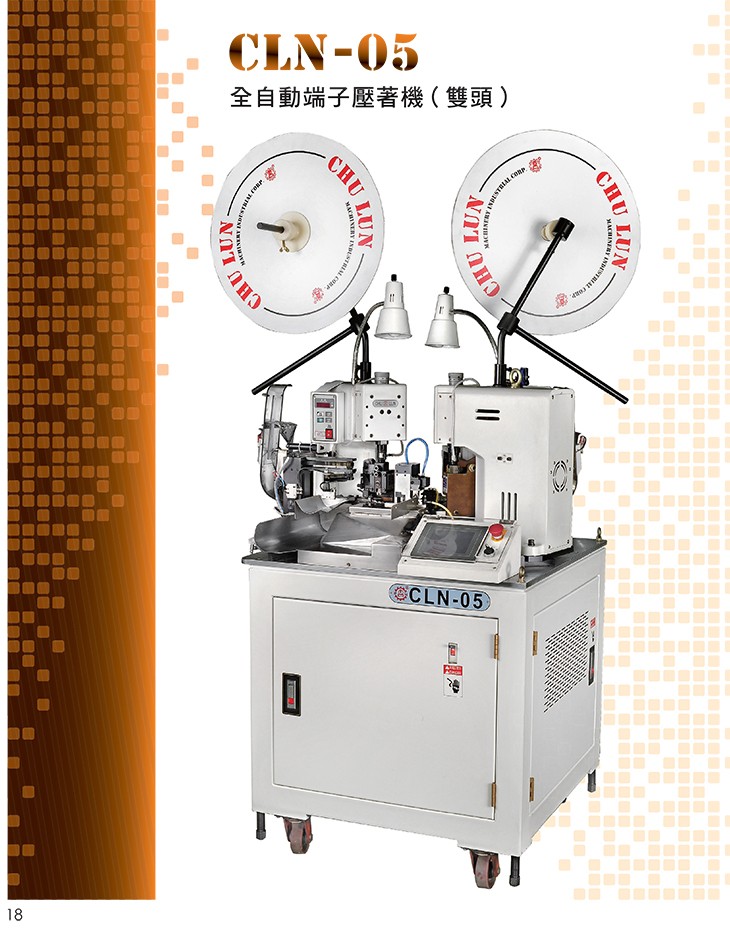

Talking about the functional advantages of the automatic terminal machine: The advantages of the automatic terminal machine are introduced as follows: the automatic terminal machine refers to a machine used in wire processing, also known as The automatic stripping and pressing end machine is a new type of equipment just released in recent years. It is a multifunctional machine integrating feeding, cutting, stripping and pressing ends. It is a humanized and intelligent high-end technical product, suitable for large and medium-sized , Small businesses, save labor. The advantages of the automatic terminal machine are high precision, fast speed, and have stripping, twisting and crimping detection systems. The digital control interface uses the integrated working power of light, electricity, machine, gas and magnetism, and imported electrical accessories, which are easy to operate and save time.

For such problems, what we have to do is to find a solution. If we want to prevent the terminal machine from being disturbed by noise, we must first choose a reasonable tool and improve its installation accuracy. ; At the same time, we must improve the cutting process of the terminal machine. If it is a slender workpiece, try to choose ninety degrees for cutting. In this way, the noise problem of the terminal machine should be alleviated.

Zhuzhou sells smart terminal machines

Pressure monitoringIf the machine is abnormal during operation. And ask the mechanics for maintenance and debugging in time, and turn off the power first. Non-designated personnel are strictly prohibited to prevent safety problems during maintenance. Debug or disassemble machine parts without permission. Be sure to turn off the power of the machine during maintenance and debugging. Clean the automatic terminal machine after use. In order to remove the debris, dust and excess oil on the surface of the pressure monitoring machine; the operator must clean the machine every day. When using a pressure monitoring machine. Oil lubrication can be added once every 12 hours, if the stamping guide rail of the terminal machine is found not to be lubricated. 2-3 drops is appropriate; at the same time, the main speed bearing of the terminal machine must be greased every week: the maintenance during such use is not to add too much oil each time.

The daily maintenance precautions of the automatic terminal machine have been introduced here. You can learn more about it, and we should pay more attention to it when we use it. This is for us There is better assistance. Be careful when using the automatic terminal machine. If you need to buy automatic terminal machines, automatic pipe cutting machines, corrugated pipe cutting machines and other mechanical equipment, you can call Contact us, and we also have punctured terminals, terminal molds, terminal copper strips and other accessories, please contact us if you have any needs

Zhuzhou sells smart terminal machines

If the machine is abnormal during the pressure monitoring operation. And ask the mechanics for maintenance and debugging in time, and turn off the power first. Non-designated personnel are strictly prohibited to prevent safety problems during maintenance. Debug or disassemble machine parts without permission. Be sure to turn off the power of the machine during maintenance and debugging. Clean the automatic terminal machine after use. In order to remove the debris, dust and excess oil on the surface of the pressure monitoring machine; the operator must clean the machine every day. When using a pressure monitoring machine. Oil lubrication can be added once every 12 hours, if the stamping guide rail of the terminal machine is found not to be lubricated. 2-3 drops is appropriate; at the same time, the main speed bearing of the terminal machine must be greased every week: the maintenance during such use is not to add too much oil each time.

It is necessary to add butter to the crimping part of the automatic terminal machine every week, and apply it evenly on the surface of the high-speed bearing and around the pressure block

Zhuzhou sales of smart terminal machine terminal refers to a machine used for wire processing. It can press five metal heads to the end of the wire and then conduct. The terminal printed by the terminal is usually for convenient connection. No welding is required, and the two wires can be connected together stably, and only need to be pulled out when disassembling. Dongguan Great Wheel Machinery Co., Ltd. has production terminal machines, you can refer to their information. When we are processing the wires, it is very troublesome if we rely on manual work. After the terminal machine is disconnected from the power supply, if the rotation has not stopped, people are not allowed at this time, so someone invented something that can help us to process the wires. Machine, terminal machine is one of them.

Zhuzhou sells smart terminal machines

Zhuzhou sells smart terminal machines

If the relay is broken,Ultra-quiet terminal machineIf the pressure monitoring frequency conversion main board is not broken, there is a problem with the relay. How to set the mute terminal inverter inverter. The original imported terminal machine inverter made by each manufacturer is different, you can refer to the manual to set up. The ultra-quiet terminal machine will not move after a long time. Look at the terminal machine motor and pedal. Is there something wrong with the circuit? It is possible that the copper sleeve is stuck, so try adding some oil.

-

2021-07-24 14:29:16Silent terminal machine inspection method

-

2021-07-24 14:24:32Weifang terminal machine manufacturer

-

2021-07-23 17:05:13Texas domestic automatic terminal machine

-

2021-07-24 14:18:51Ningbo automatic terminal machine brand

-

2021-07-23 15:21:28Silent terminal machine non-normal stop causes

-

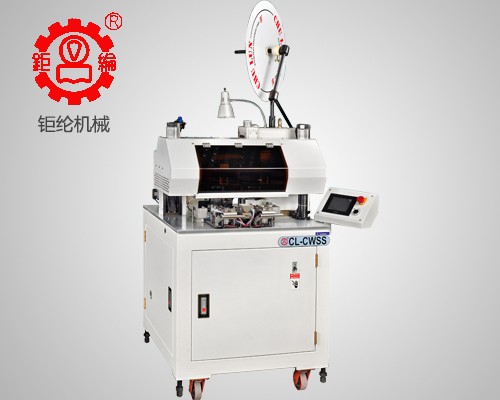

CL-HC-80-A pipe cutting machine

-

CL-540+170 Automatic Computerized Wire Cutting Machine

-

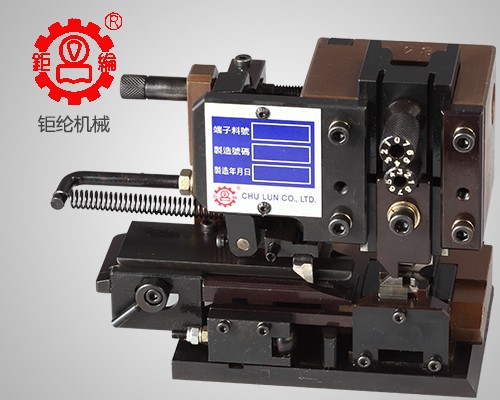

CLM-6 card die

-

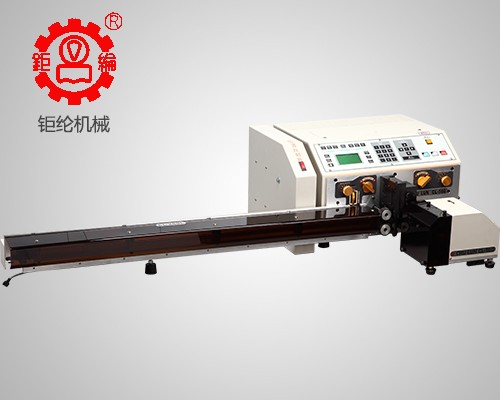

CL-560+160+260L Automatic Computerized Wire Cutting Machine

-

C1-3.0A Terminal Machine

-

C2-1.2 terminal machine

-

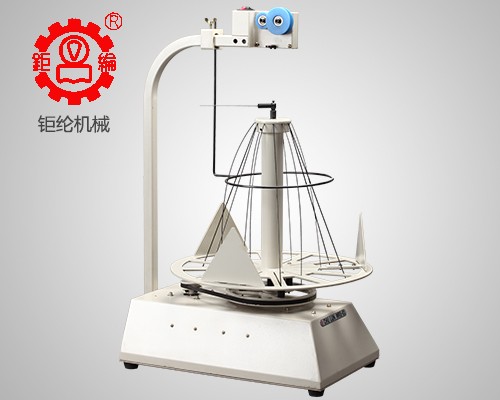

WRS-03 Restore Type Wire Discharge Machine

-

CL-2000L Super High Speed Automatic Computerized Wire Cutting Machine (Extended Type)

EN

EN

CN

CN

QQ customer service

QQ customer service