- Automatic terminal machine history and future?

- Dongguan regular ultra-silent terminal machine

- Jining stock intelligent terminal machine

- Strip tape hitting terminal machine

- Introduce the use of stripping tape hitting terminal machine specifications

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Terminal machine

Terminal machine

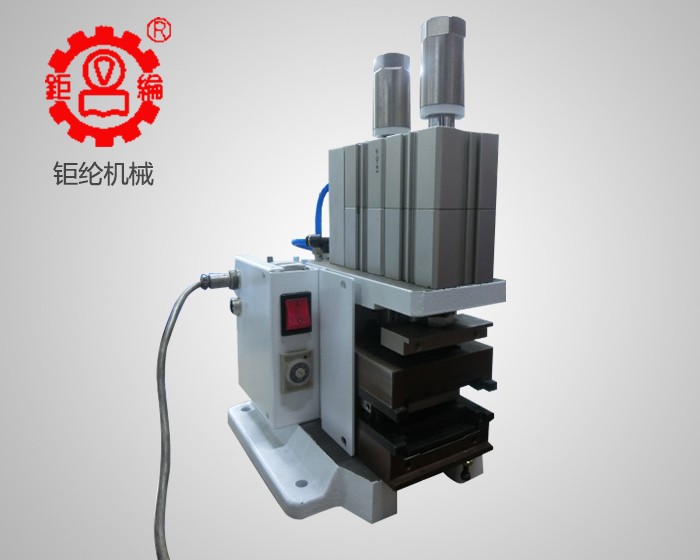

Terminal machine, a multi-function machine integrating feeding, cutting, stripping, and end pressing, humanized and intelligent high-end technical products, suitable for large, medium and small companies , Save labor. Chinese touch screen display settings, wire processing size, knife depth, terminal orientation...simplified, easy to learn and understand, repair consumables cost low. It can quickly and effectively increase production power, reduce labor costs, increase the company's profitability, and bring a certain boost to the company's livelihood development.

Terminal machineFully automatic terminal machineManual operation : ≪1> Turn the operation switch to the adjustment position ○1 (POWEROFF) and the motor will not run at this time. <2> Insert the open-end wrench into the main shaft from the rear door, and press the manual button ○2 (ADJUST) to attract the solenoid. <3> The open-end wrench rotates clockwise to drive the main shaft to rotate one round, the main machine slide block moves up and down to complete a stroke, and a terminal is crimped. <4> Keep pressing the manual button ○2 to turn it in place continuously, and then remove the open-end wrench.

Full-active terminal machine: a terminal machine that combines a server (silent type). Its operating principle is different from the usual terminal machine, only one is needed for the server Information, this information is then transmitted to the motor, and the all-active terminal machine can perform an action. All assignments are automatically completed,

The Zhuhai ultra-high-speed silent peeling terminal machine in the workshop is a fixed asset. The use date is 2012.3. The service life is 10 years. Its original value is 18,000 yuan. It is a general enterprise production equipment. The stripping terminal machine adopts the straight-line method to calculate depreciation, and the monthly depreciation amount=18000*(1-3%)/10/12=145.50. The use date is from March 2012 to July 2013, which is 9+7=16 months, and the depreciation amount in July 2013=145.5*16=2328 yuan.

What is the technological process of the terminal machine automatic terminal machine? Turn on the power switch of the automatic terminal, and the power indicator light is on. Pay attention to whether there are obvious abnormal noises inside and outside the machine. If the operation is suspended, ask the maintenance personnel to determine whether maintenance is required. Knife selection and installation: operated by designated personnel. Before installing the tool, you need to manually compare whether the selected tool matches. The tool can only be installed after the comparison is correct. After installing the tool, it must be tested manually. First, turn off the power of the automatic terminal machine, press the down touch button, and use the dedicated board to manually move the master and slave wheels to greatly increase the punching stroke of the smart terminal press. If the hand does not move, consider whether the pressure is too high or there are other problems, check and adjust to normal. Before operation, check and confirm that the locking screws are not loose.

Semi-active terminal machine: usually called terminal machine, which is the kind of vertical desktop terminal machine that we often see in shopping malls nowadays, this kind of terminal machine They all have a pedal-operated power-off clutch. When the terminal machine is running, its motor is constantly running. Each time the pedal is stepped on, it will give an “O” power-off signal to stop the operation. The price of all active terminal machines will be much lower.

Introduction to the five installation steps of the terminal machine automatic terminal machine: preparations before the operation of the automatic terminal machine: (1) Check whether the smart crimping machine and the pressure die are installed firmly, and the feet Whether the pedal switch and the power socket are plugged in securely. (2) Check whether the power supply voltage is consistent with the specified voltage (220V). (3) Fix the terminal roll and guide the terminal into the die through the guide plate. (4)Adjustment Stripping terminal machineCrimping height, manually operate the pressure test terminal. (5) After turning the spindle into place with an open-end wrench, remove the open-end wrench.

Terminal machine

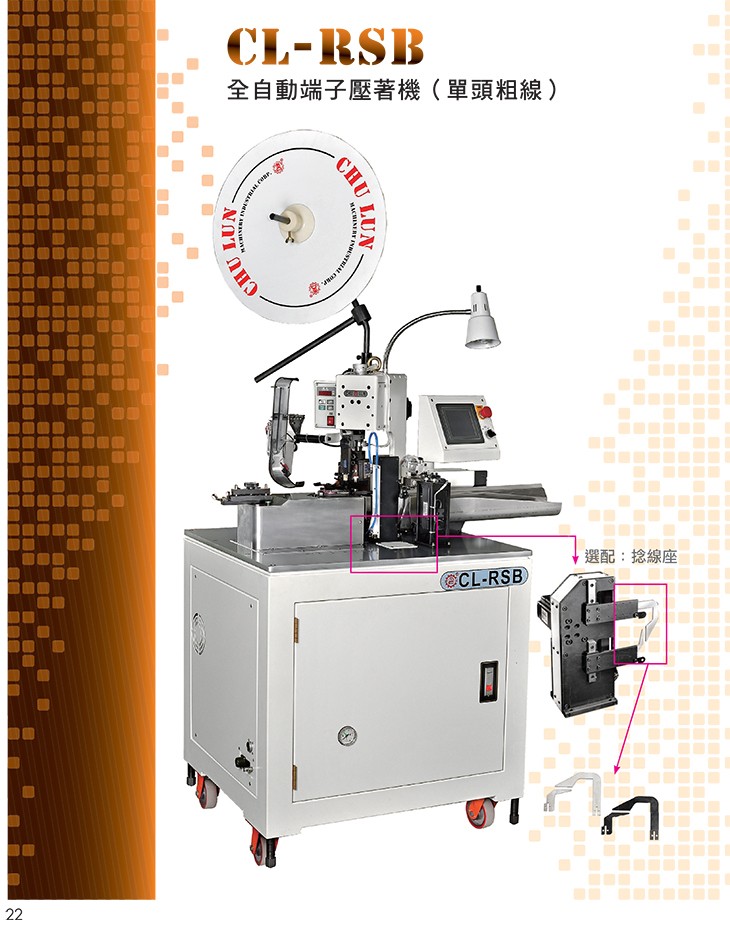

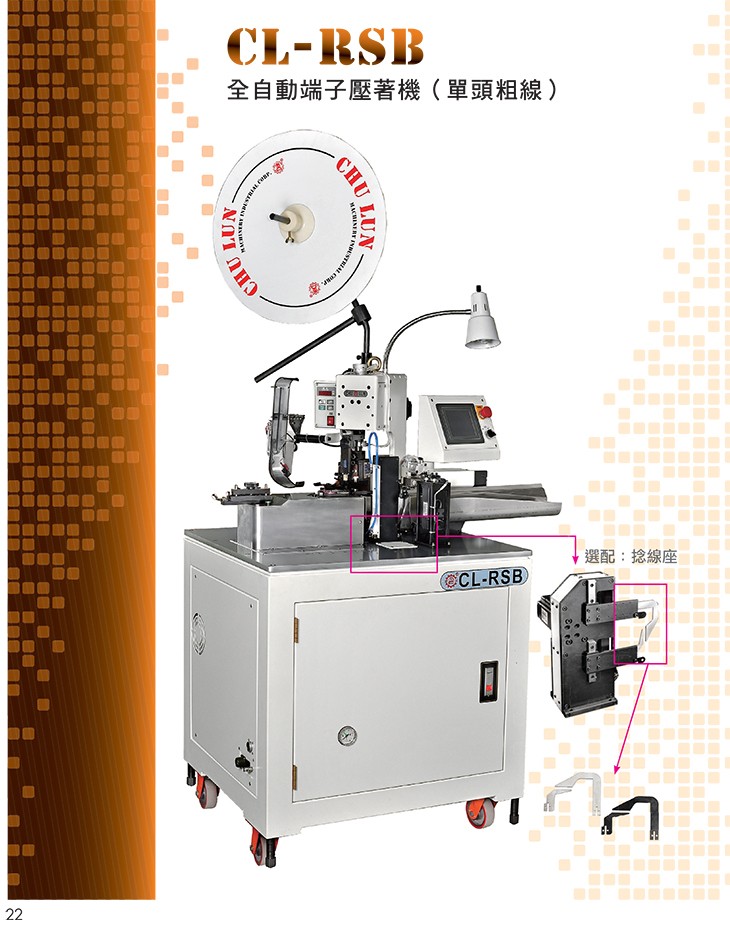

Single-head crimping terminal machine: select plc or single-chip control, servo motor or stepper motor to provide power, the production process does not require manual participation, and the production power is high. Now this type of domestic production The equipment can complete about 5000pcs wire cutting, thin-skinned, single-ended crimping terminals per hour, and can actively detect the crimping quality of the terminals.

What are the precautions when using the mute terminal machine of the terminal machine? The terminal machine is frequently connected. It may be the terminal machine, the main board of the terminal machine or the inverter is broken. Professional personnel carry out repairs. Dongguan Julun Machinery Co., Ltd. specializes in the production of wire harness processing equipment. The main products are: automatic terminal crimping machine (single-head/double-head/dip tin), computer wire cutting and twisting machine, silent terminal pressure The machine, even stripping and hitting silent high-speed terminal machines, terminal machine molds, blades and mechanical accessories and other wire harness processing equipment.

Terminal machine

If the machine is abnormal during the operation of the stripper and terminal machine. And ask the mechanics for maintenance and debugging in time, and turn off the power first. Non-designated personnel are strictly prohibited to prevent safety problems during maintenance. Debug or disassemble machine parts without permission. Be sure to turn off the power of the machine during maintenance and debugging. Clean the Zhuhai automatic terminal machine after use. In order to remove the debris, dust and excess oil on the surface of the stripper and terminal machine; the operator must clean the machine every day. When using a stripping terminal machine. Oil lubrication can be added once every 12 hours, if the stamping guide rail of the terminal machine is found not to be lubricated. 2-3 drops is appropriate; at the same time, the main speed bearing of the terminal machine must be greased every week: the maintenance during such use is not to add too much oil each time.

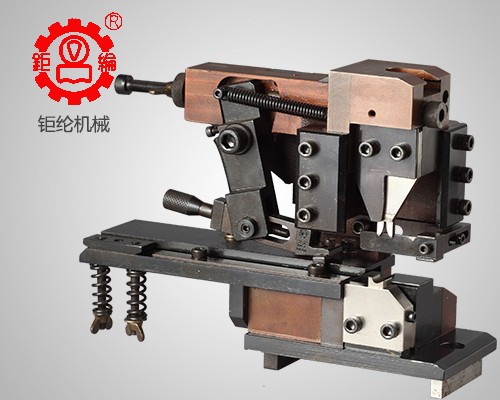

Terminal machine, automatic terminal machine, semi-automatic terminal machine working principle, diagram, according to requirements, put qualified terminals on the terminal frame, and install the terminal chain head into the equipment according to the correct method .Confirm that the die of the equipment matches the installed terminal, and then adjust the pressure of the stripping terminal machine and other parameters, and adjust the corresponding position of the terminal chain and the equipment. Take the stripped wire and check for defects, then align the wire with the slot of the terminal machine and the terminal opening, adjust the position, and then step on the foot pedal with your foot to put the terminal on the wire.

Single-head twisted wire soldering terminal machine: Choose plc or single-chip microcomputer control, servo motor or stepper motor to provide power, the production process does not require manual participation, and the production power is high. Types of domestic equipment can complete about 4000pcs of wire cutting, thin skin, single-ended crimping terminals per hour, single-ended twisting + bonding flux + tinning, and can actively detect the quality of terminal crimping, which is the degree of automation in the domestic market. One of the high terminal machines.

The smart stripping and tapping machine is a semi-automatic model. As the name suggests, it has the functions of automatic peeling and crimping of the terminals, but it requires manual feeding and manual control of the foot power switch to work. The production efficiency is high and the price is low. The intelligent terminal machine of the ultra-quiet terminal machine server (inverter) is a semi-automatic model, which requires manual feeding and manual control of the foot pedal power switch to work. The working principle is similar to the stripping terminal machine, but it does not have the automatic thinning function (usually used in conjunction with the computer wire cutting machine), low energy consumption and low price.

Terminal machine

Terminal machine

The Zhuhai ultra-high-speed silent peeling terminal machine in the workshop is a fixed asset. The use date is 2012.3. The service life is 10 years. Its original value is 18,000 yuan. It is a general enterprise production equipment. The stripping terminal machine adopts the straight-line method to calculate depreciation, and the monthly depreciation amount=18000*(1-3%)/10/12=145.50. The use date is from March 2012 to July 2013, which is 9+7=16 months, and the depreciation amount in July 2013=145.5*16=2328 yuan.

-

2021-07-24 15:58:23Xianyang small semi-automatic terminal machine

-

2021-07-23 17:10:31Wuhu automatic terminal machine factory

-

2021-07-24 14:29:16Silent terminal machine inspection method

-

2021-07-24 14:54:15High-end terminal machine

-

Fully Automatic Terminal Crimping Machine (Single Head Waterproof Bolt)

-

CLM-2S card module

-

CLM-4E card die

-

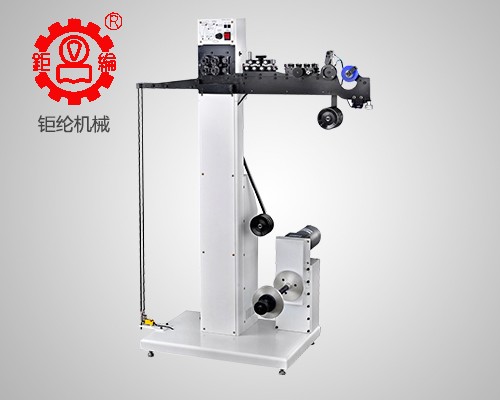

WRS-04+05 Shaft loading type wire release machine + wire feeder

-

WRS-07 Multifunctional Wire Feeder

-

CL-2000L Super High Speed Automatic Computerized Wire Cutting Machine (Extended Type)

-

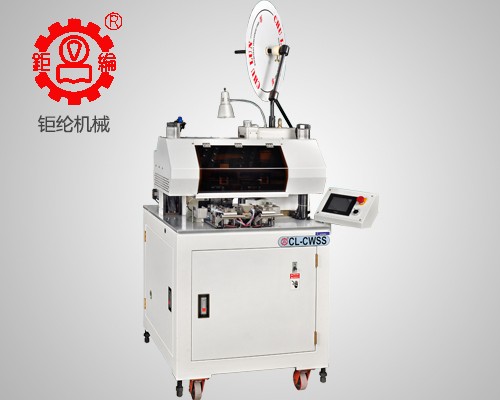

CL-CWSS Single-head pole short wire dip tin machine

-

Intelligent terminal machine

EN

EN

CN

CN

QQ customer service

QQ customer service