- Maoming stripping tape hitting terminal machine manufacturer

- Dongguan regular ultra-silent terminal machine

- Intelligent terminal machine

- Automatic terminal machine production precautions

- Lianyungang stripping tape hit terminal machine processing

Contact Person: Miss Wang

Phone: 15999898070

Telephone: 0769-87883409

Email: cl-tk@chulun.com.tw

Address: Room 101, Building 4, No.8 Qinghe Road, Huangjingkeng, Huangjiang Town, Dongguan City, Guangdong Province

Strip tape hitting terminal machine

Automatic terminal machine is one of the products we use more, but there is another product that is semi-automatic terminal It means that half of this kind of products is also required manual. The two are different terminal machine equipment, so the working methods are also different. It can be said that the difference is still quite big, but we have Have you understood the main difference between the automatic terminal machine and the semi-automatic terminal machine?

Characteristics of the semi-automatic terminal machine for stripping and crimping machine: The processing project of the semi-automatic terminal machine requires manual participation, and it is suitable for all kinds of complex shielded wires and multi-core wires. , Carry out the terminal step separately. The terminal machine and the automatic terminal machine have the same points: simple operation and quick use, which are different from the previous manual crimping method, which greatly improves the production efficiency. Improve production capacity for the factory. At the same time, it also saves a lot of costs for the factory. Dongguan Julun Machinery Co., Ltd. is at your service. Consulting Tel: 0769-87883409

1. The automatic terminal machine is fully intelligent and automatic. It integrates integrated circuits, servers, manipulators, detection signals, and integrates all the production processes of wire processing into one power supply Line processing equipment. A lot of manual operations can be saved during operation, only the operation method needs to be set, and a work signal is given to the server. This signal will be transmitted to the work drive motor through a series of components, and then the work can be started and stopped. The entire work process is completed automatically, so work efficiency is higher and manpower can be saved.

The debugging of Xinxiang terminal machine is mainly mold debugging, and this part of the mold is divided into feeding and blade debugging. Generally speaking, the terminal machine blade has 4 blades, and there are 2 blades. The lower knife is 2 pieces, the upper knife is divided into the inner knife and the outer knife, and the lower knife is the same. You understand that the next step of debugging pressure monitoring is much easier. You must manually debug the pressure monitoring operation. One is safe, and the other is us. It can be seen by manual debugging whether the crimped terminal meets the requirements. The professional terminal crimping grid mainly depends on the crimped copper wire. Because this is conductive, it is critical. If it is too tight, the copper wire will be broken or directly affected. If the blade is broken, the terminal and wire will easily fall off if it is loose.

Stripping and tapping terminal machine

2. Semi-automatic terminal machine is a more common terminal machine equipment, we all refer to it collectively as terminal machine. Semi-automatic terminal machine used to be the most used equipment on the market because of its strong applicability. The semi-automatic terminal machine is controlled by a foot-operated power-off clutch device through manual foot-stepping to control the machine's terminal action. The processing action of the semi-automatic terminal machine is single, as long as the terminal is tapped, and the wire material also requires manual separation and wire feeding. The work efficiency is lower than that of the automatic terminal machine.

The stripping terminal machine detects whether the terminal is qualified, it needs to pass the terminal cross section analyzer, the process is divided into: cutting-grinding and polishing-electrolysis (corrosion)- ----Observe that the debugging of professional terminal machine is mainly about mold debugging, and this part of the mold is divided into feeding and blade debugging. Generally speaking, professional terminal machine blades have 4 blades, 2 upper blades, 2 lower blades, and upper blades. Divide the inner knife and the outer knife, and the knife is the same. You understand that the next step of debugging is much easier. You must perform manual debugging. One is safe, and we can see the crimped terminals in manual debugging. Whether it meets the requirements, the terminal crimping grid mainly depends on the crimping copper wire.

Stripping and tapping terminal machine

Because the price of fully automatic terminal machines is higher than that of semi-automatic terminal machines, most of the terminal machines of many companies are still semi-automatic terminal machines. However, with the progress of the times, fully automatic terminal machines have become the core equipment of automated wire processing companies. Following the development of the company, fully automatic terminals will gradually replace semi-automatic terminal machines. This is the future direction of the company.

Stripping and tapping terminal machine

The stripping terminal machine can be a small baffle in the front. What are the corresponding parameters of the mute terminal machine P000~005? If you know, please advise me, thank you? I don't know, help you expand it. Where is it not the same? What is the difference between Xinxiang mute terminal machine 1T and 2T? When it comes to silent terminal machines, you will ask about 1T and 2T. Next, Dongguan Julun Machinery will talk about the difference between them. The mute terminal machine first uses variable frequency motors. The main difference lies in the power and range of use of the motor. The 1T mute terminal machine is fixed on the machine and is only suitable for crimping small horizontal feed terminals. The 2T silent terminal machine is separated from the mold, so the 2T can crimp larger terminals and is suitable for direct, horizontal, and single terminals.

If you need these two products or terminal molds, terminal copper strips, piercing terminals, automatic pipe cutting machines and other mechanical equipment, you can contact our semi-automatic terminal machine manufacturer , Welcome our calls.

The stripping and crimping machine realizes "ultra-high-speed processing" of fully automatic crimping at both ends of 9000 pieces per hour! Equipped with standard equipment for pressure testing! Pressure monitoring"Simple|Small" has unprecedented performance and amazing processing ability, which is a thorough The next-generation fully automatic crimping machine that has changed the concept of wire processing machines. This model has original ideas and creations, which not only improves the performance of the machine, but also reduces the burden on the operators through the simplification of operating procedures and die exchange. In addition, from the operator’s point of view, pressure monitoring saves space due to the greatly reduced volume and miniaturization of accessories.

Stripping and tapping terminal machine

Stripping and tapping machine

Strip terminal machine Xinxiang computer wire cutting machine safety operating procedures: 1. When pressure monitoring adjustment and paper cutter replacement, it must be shut down. Even when the machine is stopped, it is strictly forbidden to put your hands under the knife to change the knife. Long-handled bolts and other tools should be used to change the knife. They must be removed during the test run to avoid injury to the operator when the machine is started. 2. The power supply must be blocked when the pressure monitoring machine is adjusted, the blade is exchanged, and the oil is repaired, scrubbed and inspected. Dongguan Julun Machinery Co., Ltd. welcomes new and old customers to come to negotiate.

-

2021-07-23 16:40:15Lianyungang stripping tape hit terminal machine processing

-

2021-07-24 14:43:38Intelligent terminal machine

-

2021-07-23 16:46:05Huzhou terminal machine cost

-

2021-07-23 15:23:06Automatic terminal machine history and future?

-

2021-07-24 14:06:14Maoming stripping tape hitting terminal machine manufacturer

-

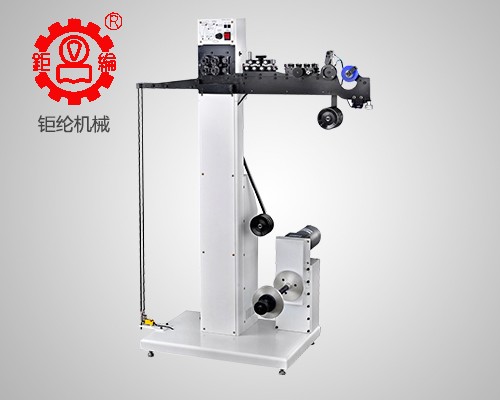

WRS-07 Multifunctional Wire Feeder

-

CL-FSH Hanging pressure detector

-

C1-3.0A Terminal Machine

-

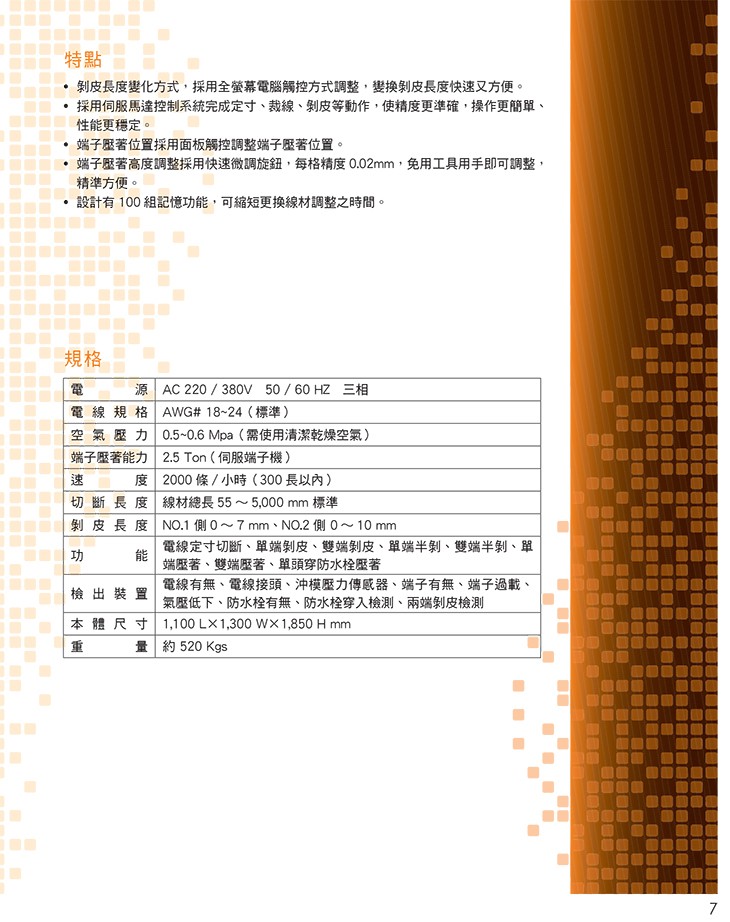

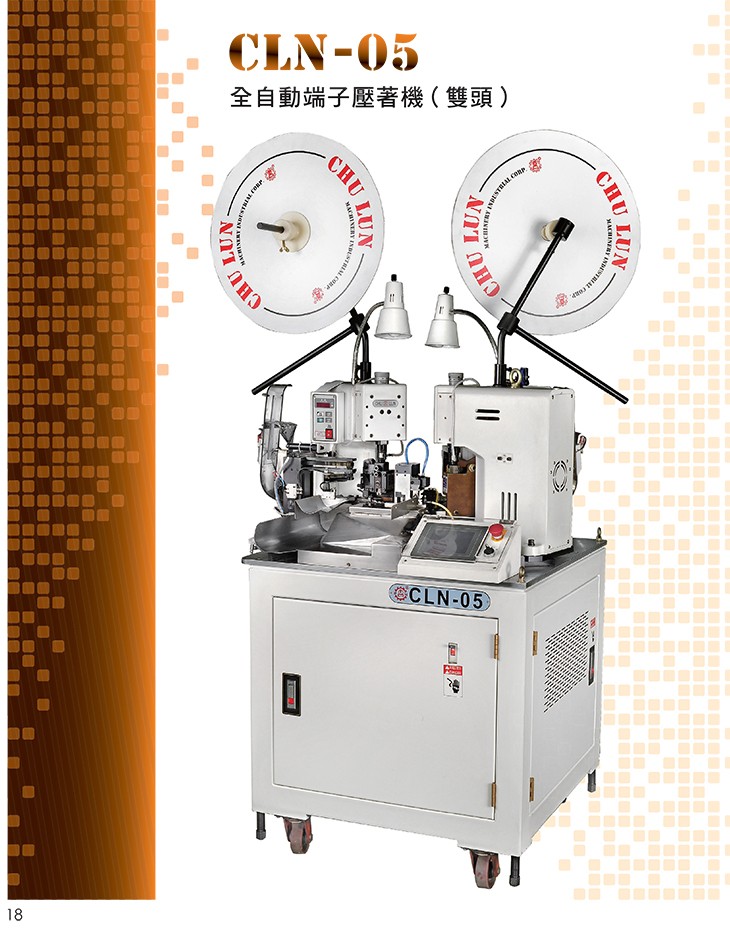

CLN-06 Automatic terminal crimping machine (thick wire)

-

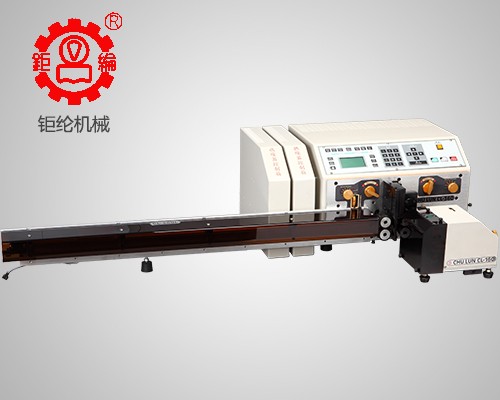

CL-360+160+260L Automatic Computerized Wire Cutting Machine

-

C3-2.5S High-speed stripping and pressing machine

-

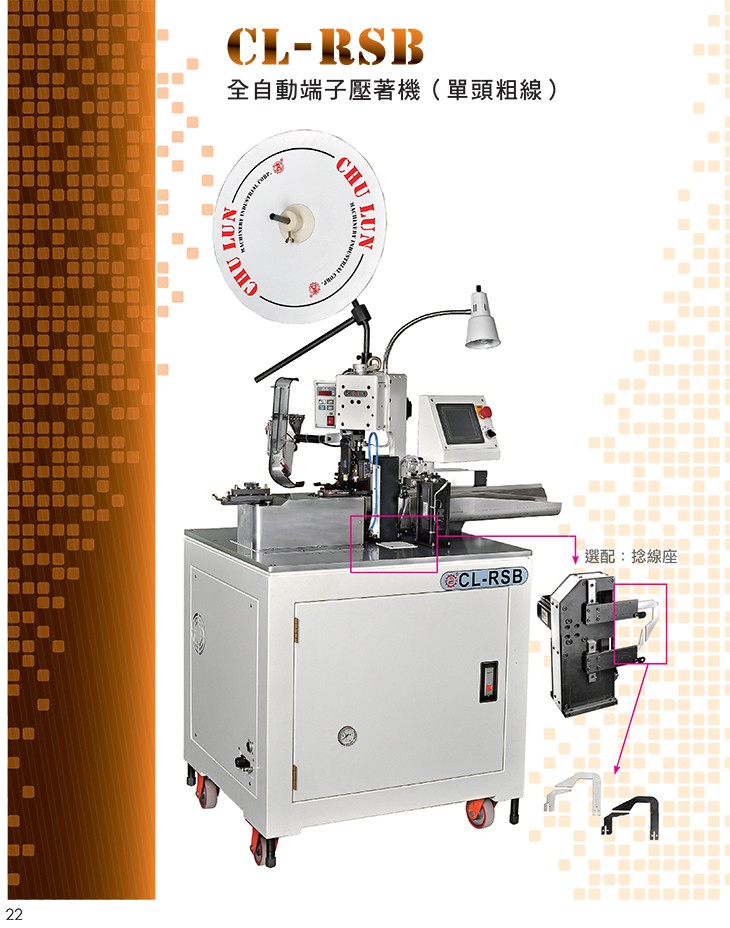

Fully Automatic Terminal Crimping and Twisting Wire Solder Dabbing Machine (Single Head Waterproof)

-

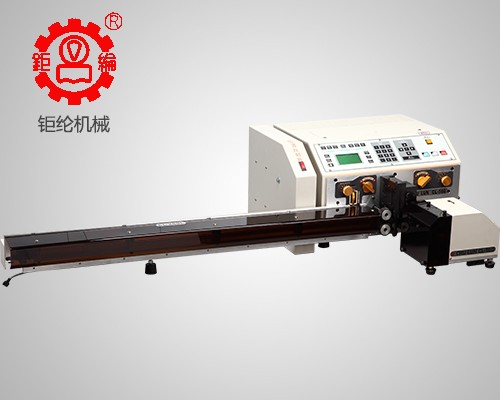

CL-560+160+260L Automatic Computerized Wire Cutting Machine

EN

EN

CN

CN

QQ customer service

QQ customer service